Topics

Real-time monitoring in Additive Manufacturing

Real-time monitoring in Additive Manufacturing

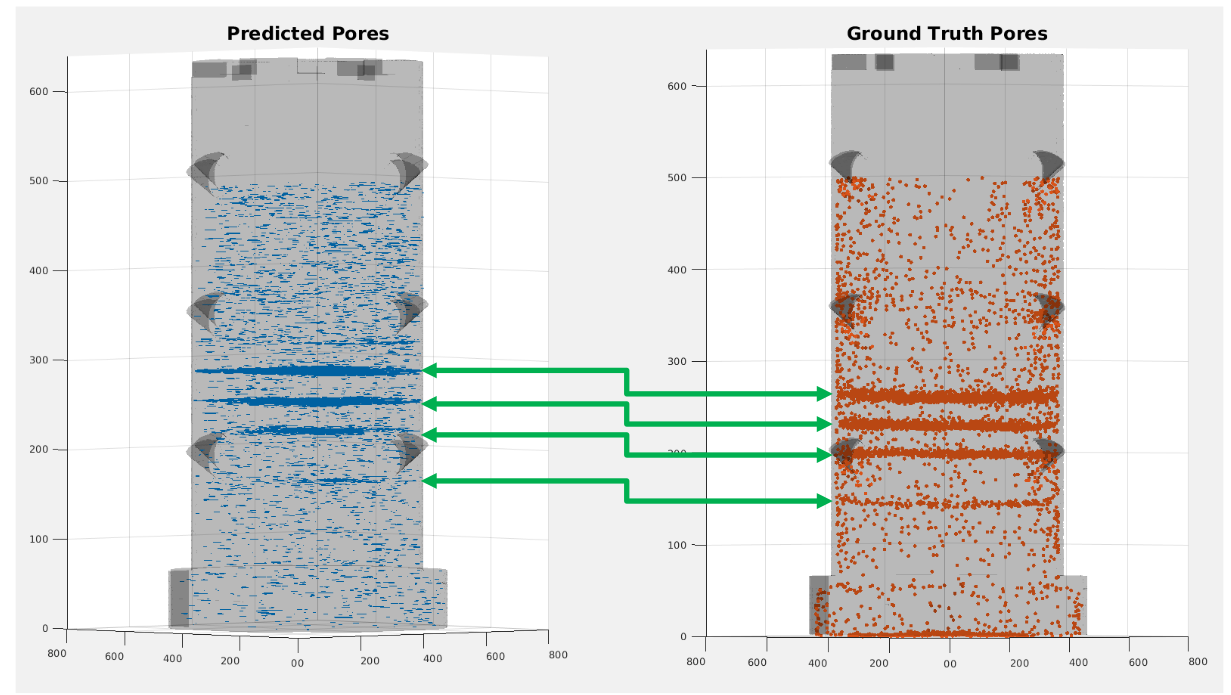

In additive manufacturing, items are 3D printed layer-by-layer using materials like plastics, polymers, and metals. Unfortunately, instabilities in the printing process can produce defects like cracks, warping, and pores/voids within the printed item. Our goal at IPI is to develop computer vision systems that identify the creation of these defects in real time, then provide the 3D printer with sufficient information to intervene in a way that corrects, or avoids, the defect. Since these defects can occur over a very short amount of time (< 1 ms), our monitoring systems need to operate at very high speeds while also providing accurate results.

Using high speed cameras and photodiodes (sampling rates > 20 kHz), we are exploring AI models that can highlight defect creation. One approach we have developed is to employ anomaly detection algorithms to highlight all abnormal painting behavior, combined with active learning to refine the AI anomaly detection model in step with the changing print environment. A second approach we are exploring is the training of AI models based on the non-destructive testing techniques (e.g. CT imaging) of previously-printed items. In both scenarios, Quasar’s GPU acceleration is being explored to obtain the required real-time performance.

Related:

- IPI Additive Manufacturing Research Highlighted in Recent Youtube Video

- Webinars: AI for Manufacturing

Relevant Projects: Vision-in-the-Loop, AI Flanders

Contact: dr. Brian Booth